The Farrel Corp. was scheduled to unveil its new HQ May 4. Here is Valley Indy reporter Ethan Fry’s description of the building from an article published Feb. 4

The Farrel Corp. was scheduled to unveil its new HQ May 4. Here is Valley Indy reporter Ethan Fry’s description of the building from an article published Feb. 4

Decades ago, the Farrel Corp. employed 3,000 people in Ansonia.

The workforce — and the company, and the city — had a rough few years.

But officials hope a gleaming new $11 million headquarters overlooking downtown may be a much-needed catalyst in the city’s long-sputtering efforts at economic renewal.

Background

Now named Farrel Pomini, the company began in the 1840s as a foundry. Like many Yankee companies that began during the Industrial Revolution, it boomed during the Civil War.

The Farrel name became synonymous with power in Ansonia — commercially and politically. An oil painting of company founder Franklin Farrel still hangs in Ansonia’s Aldermanic chambers.

As the company grew, it expanded and diversified by merging with Birmingham, a Derby-based foundry.

As the 20th century drew to a close, though, the company shed most of its 15 product lines — and most of its employees, the work force shrunk by pressures from things like globalization and outsourcing. There are now about 100 working people at the company, which is a subsidiary of a German conglomerate.

In mid-2014, Ansonia was in danger of losing Farrel completely. It announced that it was looking to consolidate its operations — then split between downtown Ansonia and another location in Oxford — in a new headquarters.

Oxford, one of the fastest growing communities in the state, with a mill rate dwarfing Ansonia’s, might have seemed like the logical choice.

But the company said it wanted to stay in Ansonia, where it had always had roots. In February 2015 Aldermen committed $1 million of public money to build a road to a new building in the long-stagnant Fountain Lake commerce park.

A federal grant eventually reimbursed the city, and a state loan helped the company pay for construction.

Farrel Pomini became the industrial park’s first tenant last year.

Paul Zepp, the company’s CFO and chief of operations, took the Valley Indy on a tour of the facility last month.

Paul Zepp, the company’s CFO and chief of operations, took the Valley Indy on a tour of the facility last month.

Significant Investment

The company is a subsidiary of HF Mixing Group, an industrial conglomerate based in Lubeck, Germany.

Zepp said his bosses had a simple instruction when it came to the new building — make it the best you can.

If you had ever ventured in to the company’s prior headquarters — spread across several old buildings on upper Main Street — it shows.

Fully furbished with all new equipment, the new headquarters cost a total of $10.8 million, Zepp said.

“They were really adamant: ‘You only do this once every 30 years, so do it right,’” Zepp said. “They said, ‘We don’t want to see old stuff in a new building.’”

Plastics

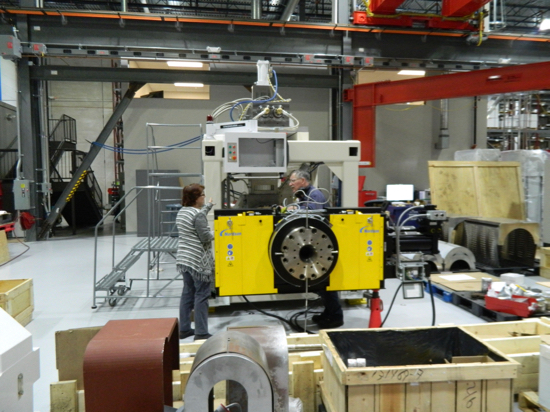

The company now focuses on making machines that other companies use to mix plastics.

During last month’s tour employees were working on mixers that were headed to Mexico and China.

The product line began in 1963, and the company still has four or five long-term customers who have been using its machines since, Zepp said.

The company prides itself on providing customers with highly customized products.

“They have their own formulations and tweaks — what temperature they like to raise it to, how long it’s mixed for, how it’s cooled down,” Zepp said. “They all try to get an advantage over one another.”

“Our process for mixing plastic is different than our competitors’,” Zepp said. “So our equipment is actually more expensive, but it allows the customers to mix in a lot of less expensive fillers.”

The new building totals about 60,000 square feet, about 16,000 of which is office space — research and development, sales, engineering, purchasing, operations, and administration.

The space has an industrial look, with polished concrete and exposed ceilings.

“That’s a really popular thing on old buildings — you go in and gut them and leave them open,” Zepp said. “We said ‘Why don’t we start a new building like this?’”

The building’s vantage point also affords a spectacular panorama of much of the city — including the old Farrel-Birmingham complex downtown.

There are also conference rooms with smartboards and videoconferencing capabilities.

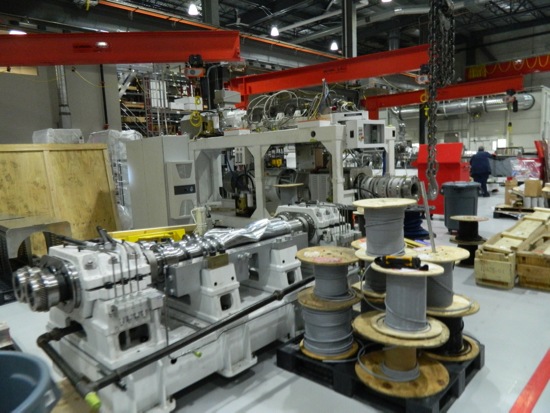

The remaining 40,000 or so square feet are devoted to storage, assembly, manufacturing, repair, and shipping.

The new building gave the company a much more customizable space that streamlines the production process, Zepp said.

For example — a 40-ton overheard crane spans the entire production floor.

“You can pick up stuff at one end of the floor and bring it all the way to the other end, no problem,” Zepp said. “It’s 80 feet wide. In the old building it was only 55 feet wide. When we tried to assemble a machine we were never able to lay a machine out the way we wanted to. Now we can do two rows of machines at a time.”

There’s also an automated “storage shuttle” to allot space for parts and materials more efficiently and a paint shed big enough for a tractor-trailer.

If that sounds like overkill, it isn’t — during last month’s tour employees were working on assembling and testing one mixer so big it will span two floors when installed in a customer’s factory.

The machine, along with all the components connected to it, will sell for about $1.7 million, Zepp said.

After employees test them to make sure they work, the machines are usually loaded onto flatbeds and driven to the New York City for shipping.

About 80 percent of the company’s products go overseas.

’Everything Is Beautiful’

The company obviously isn’t the industrial powerhouse it once was.

But Zepp said it’s forging a path forward in a new economic reality, which is more than you can say for many others.

“We never would have been able to survive if we hadn’t outsourced a lot of that,” he said. “We would have just lost to the competition and even this part of it wouldn’t be left.”

He said he’s reminded every day of the Farrel’s rich history in the community.

“Wherever I go I say ‘I work at Farrel,’” he said. “People say ‘Oh, my grandfather worked there,’ or ‘My uncle worked there.’”

Zepp said he hopes the company’s new roots show people it’s here for the long haul.

Mayor David Cassetti said the new building is “phenomenal,” and that he wants to hold a “State of the City” event there.

The company and city are also working on scheduling a grand opening celebration.

The mayor said he hopes other tenants may soon follow Farrel’s example in relocating to the industrial park.

“Everything is beautiful up there,” Cassetti said.